Safe Lifting Europe Completes 1,760-Tonne Overload Test on Liebherr TCC 78000 Crane in Rostock

- Meagan Wood

- Dec 9, 2025

- 3 min read

30-Second Takeaway

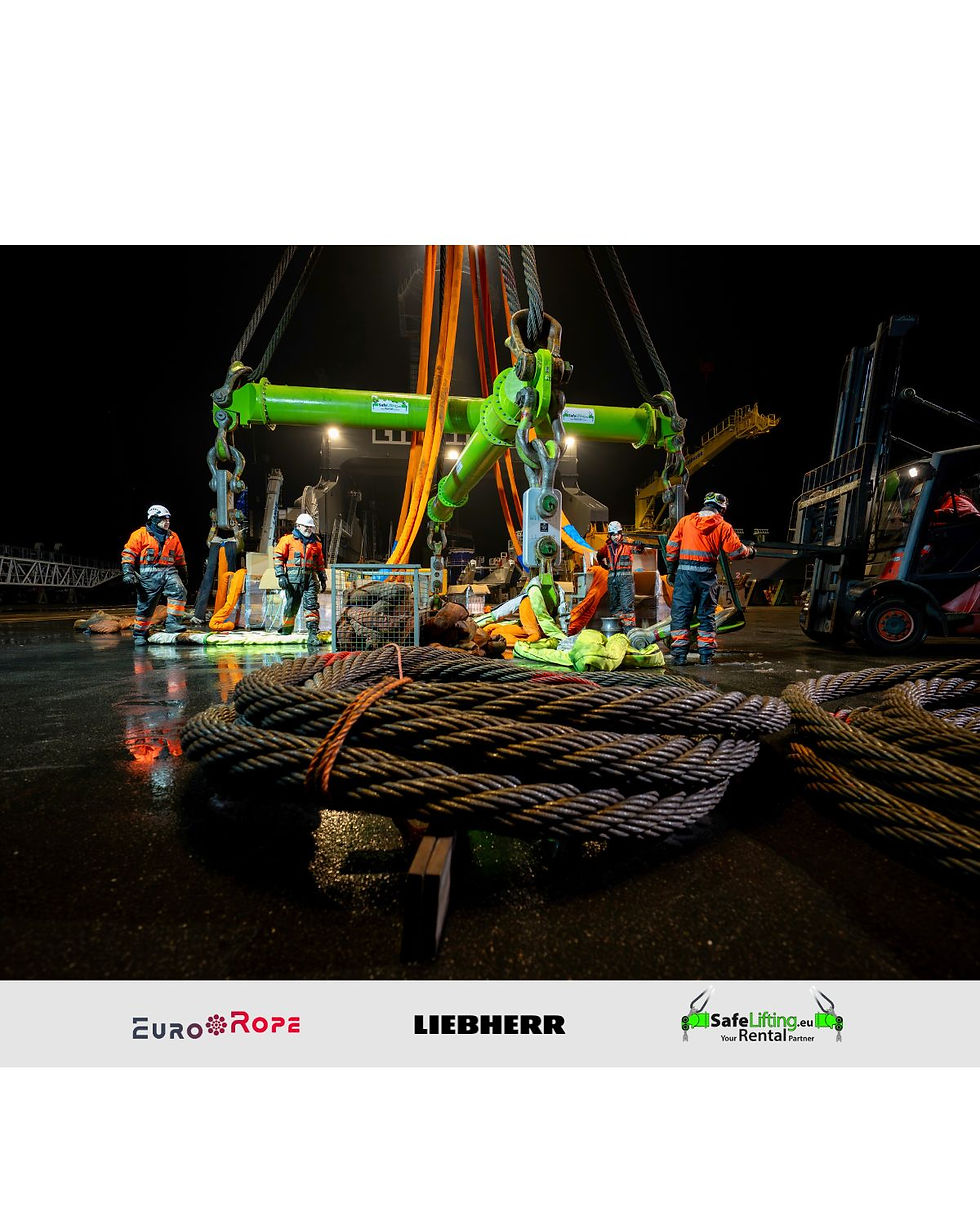

Safe Lifting Europe B.V. has successfully completed a 1,760-tonne overload test on the 1,600-tonne Liebherr TCC 78000 crane in Rostock, Germany. Delivered as a full turnkey operation on short notice, the project was completed ahead of schedule, demonstrating Safe Lifting Europe’s in-house engineering capability, speed of mobilisation, and expertise in large-scale load testing.

Major Overload Test Highlights Heavy-Lift Capability

Safe Lifting Europe B.V. has marked another significant milestone with the successful execution of a 1,760-tonne overload test on the 1,600-tonne main crane of the Liebherr TCC 78000 in Rostock.

The project underscored the company’s ability to deliver quality under pressure, combining engineering expertise, rapid mobilisation, and precise execution in a high-stakes heavy-lift environment.

Safe Lifting Europe extended its thanks to Liebherr Maritime Cranes, Marten Frier, and Robert Kidzuhn for the opportunity and for placing their trust in the company’s equipment and services.

Rapid Mobilisation on Short Notice

Despite receiving the request at short notice, Safe Lifting Europe moved quickly to secure the assignment.

Within one week, the team:

Finalised the scope and engineering approach

Mobilised all required materials

Transported equipment to Rostock using six full truckloads

The objective was clear: perform a 1,760-tonne overload test using Safe Lifting Europe’s own equipment and a complete water-bag load testing system.

Turnkey In-House Load Testing Solution

Safe Lifting Europe delivered a complete in-house service, providing every element required for the test, including:

Engineering and load calculations

Detailed drawings and test procedures

Shackles and grommets

Polyester roundslings

HMPE roundslings

Spreader systems

Water bags

Load cells

Pumps

Over 1,000 metres of water-filling hoses

This turnkey approach ensured full control over quality, safety, and execution throughout the operation.

Technical Challenges Managed with Precision

The test was carried out 50 metres off the quay, introducing additional complexity. Ensuring sufficient water flow at this distance was critical to achieving the required test load.

Through meticulous planning and experienced execution, Safe Lifting Europe ensured stable filling rates, accurate load control, and safe system performance throughout the test.

Completed Ahead of Schedule

Despite the complexity and scale of the operation, the overload test was completed ahead of schedule, enabling Liebherr Maritime Cranes to resume normal operations sooner than anticipated.

This outcome reflected Safe Lifting Europe’s core strengths: speed, precision, and reliability, even under tight timelines.

Quality, Speed, and Complete In-House Service

The Rostock overload test exemplifies Safe Lifting Europe’s operating philosophy:

Quality in engineering and execution

Speed in mobilisation and delivery

Complete in-house service, minimising reliance on third parties

A special acknowledgment goes to the Safe Lifting Europe team for their professionalism, commitment, and technical expertise in delivering another complex heavy-lift testing project.

Photography by

Gerard van Dam

About Safe Lifting Europe B.V.

Safe Lifting Europe B.V. is a specialist provider of heavy-lift load testing, engineered lifting solutions, and rigging services for the global crane, offshore, port, and industrial sectors.

The company is known for delivering turnkey overload and load testing services, supported by fully in-house capabilities including engineering, certified lifting gear, water-bag systems, load monitoring, and logistics. Safe Lifting Europe regularly executes tests ranging from small lifting devices to ultra-heavy cranes exceeding 1,000 tonnes, with a strong focus on safety, precision, and speed.

By maintaining full control over equipment and engineering, Safe Lifting Europe ensures consistent quality and rapid response for complex projects worldwide.

Website: https://www.safeliftingeurope.com

About Liebherr Maritime Cranes

Liebherr Maritime Cranes is a global leader in the design and manufacture of ship, offshore, port, and heavy-duty cranes, serving maritime and industrial customers worldwide.

As part of the Liebherr Group, the company delivers advanced crane solutions known for reliability, innovation, and engineering excellence. Liebherr’s maritime cranes are used in shipyards, ports, offshore installations, and industrial facilities, where performance and safety are critical.

Frequently Asked Questions

What is an overload test and why is it required?

An overload test verifies that a crane can safely handle loads exceeding its rated capacity, ensuring structural integrity, system performance, and compliance with certification requirements.

Why was a 1,760-tonne test performed on a 1,600-tonne crane?

Overload tests are typically conducted above nominal capacity to confirm safety margins and validate crane performance under extreme conditions.

What role do water bags play in load testing?

Water bags allow precise, incremental load application, making them ideal for large-scale and controlled overload testing.

Why is in-house service important for heavy-lift testing?

In-house engineering, equipment, and logistics reduce risk, improve coordination, and ensure accountability throughout the testing process.

What made this project particularly challenging?

Short mobilisation time, large test load, offshore-style conditions 50 metres off the quay, and high water flow requirements all added complexity.

Comments